Railway Grinder manufacturer and supplier

Railwaycare Professional Rail Grinding Solutions for Maintenance Safety and Full Lifecycle Optimization

RailwayCare delivers a full portfolio of advanced Railway Grinders (Railway Grinding Machines and Railway Grinding Train) designed to restore rail profiles, eliminate surface defects, reduce rolling noise, and extend rail life.

With proven engineering experience, global technical support, and a strong focus on precision grinding technology, RailwayCare equips railway operators, metro systems, and maintenance contractors with safe, reliable, and cost-effective rail grinding solutions.

Rail grinder

What Is a Rail Grinder and Why Is Rail Grinding Essential?

In the railway maintenance industry, the term "Rail Grinder" encompasses both large-scale Railway Grinding Trains and portable Railway Grinding Machines.

Railway Grinding Train

A Railway Grinding Train is a large, self‑propelled track maintenance machine that integrates an operating system with its own power system. It is designed for continuous rail profile restoration, corrugation mitigation, and preventive maintenance over extended distances, making it ideal for mainlines, station tracks, and other long‑range applications.

Railway Grinding Machine

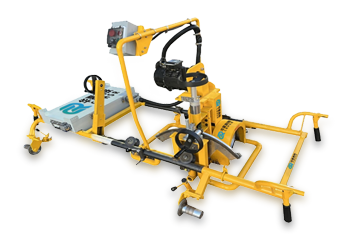

A Railway Grinding Machine is a hand‑held or small self‑guided unit that performs localized, precision repair and contour finishing using a single grinding head. It is specifically used for detailed work on welds, turnouts, and isolated rail defects, providing essential spot‑treatment and supplementary grinding in areas where larger grinding trains cannot operate.

Railway maintenance

Why is Track Grinding So Important?

Rail grinding is a critical component of track maintenance and an effective measure for preventing and addressing rail defects. Through rail grinding, the wheel-rail contact relationship can be optimized, effectively preventing or delaying the occurrence of defects such as contact fatigue, wear, and corrugation. It also repairs or mitigates rail surface damage, significantly reducing the risk of rail fractures. Consequently, it extends the service life of track infrastructure and lowers the lifecycle maintenance costs of the railway system.

Features

Features of Railway Grinding Machines

| Category |  Railway Grinding Train Railway Grinding Train |  Railway Grinding Machine Railway Grinding Machine |

| Power Type | Self‑propelled (Diesel/Electric drive) | Hand‑held (Electric/Hydraulic) or small self‑guided |

| Function | Line‑level systematic maintenance | Localized precision repair |

Operation Mode | Automated continuous operation with multi‑head array | Manual operation with a single grinding head |

| Tasks | Profile uniformity, corrugation elimination, preventive grinding | Local defect treatment, weld finishing, defect repair |

Application Scenarios | Mainline sections, station turnouts, and long‑distance continuous grinding | Local areas such as turnouts, welds, and curve transition zones |

Operating Speed | 3‑16 km/h | 1‑2 km/h |

Surface Roughness | < Ra 10 μm | ≤ Ra 6 μm |

Grinding Accuracy | ≤ ±0.2 mm | ≤ ±0.1 mm |

products

Explore RailwayCare's Professional Rail Grinders

Railway Grinder

A Railway Grinding Train is a large, self‑propelled track maintenance machine that integrates an operating system with its own power system.

| Image | Railway Grinder | Model | Description | More |

|---|---|---|---|---|

| Lithium Battery Vertical Axis Turnout Grinder | Rail Grinding | Rail Grinder | CM-4.7II | The CM-4.7II is a new generation of eco-friendly intelligent grinding equipment | |

| Multifunctional Vertical Axis Grinder | Rail Grinding | Rail Grinder | NCM-5 II | The NCM-5 II Multifunctional Vertical Axis Grinder is a lightweight yet powerful dedicated equipment for track maintenance | |

| Internal Combustion Intelligent Copying Rail Grinder | Rail Grinding | Rail Grinder | NGM-6.3 II Internal Combustion Intelligent | The NGM-6.3 II Internal Combustion Intelligent Copying Rail Grinder is a smart construction equipment | |

| Profile Rail Grinder | Track grinding | Lithium-Powered | Lithium-Powered Multi-Function | The machine uses a lithium battery as its power source and grinding discs as the abrasive medium | |

| Rail Grinding Train | Grinding Train | Rail Grinder | GMC16A | The GMC16A Rail Grinding Train is designed for both preventive and corrective grinding of tracks and turnouts. |

Product Application Scenarios

Main Types of Rail Grinders for Your Needs

Typical Applications

Rail Grinder Use Cases

A Brief Analysis of Common Defects in Rail Grinding

Rolling Contact Fatigue (RCF)

Rolling contact fatigue in rails often occurs simultaneously with rail wear. Based on severity, rail fatigue damage can generally be classified into three stages: micro-cracks, minor shelling cracks, and severe shelling cracks or shelling spalls.

Grinding Method:

Preventive grinding is employed to delay and control the initiation and propagation of cracks. When fish-scale shelling cracks or spalling occur, grinding (or milling) should be scheduled promptly.

The grinding volume is determined based on the measured deviation between the actual rail profile and the target profile, as well as the degree of fatigue damage. For tangent tracks and the inner rails on curves, the focus is on grinding the crown area, followed by coverage of the entire crown surface.

The grinding volume is determined based on the measured deviation between the actual rail profile and the target profile, as well as the degree of fatigue damage. For tangent tracks and the inner rails on curves, the focus is on grinding the crown area, followed by coverage of the entire crown surface.

Corrugation

Corrugation typically manifests as alternating wide and narrow bright bands on the rail crown. It is commonly described by wavelength and peak-to-trough value. Wavelength refers to the longitudinal distance between two adjacent crests, while peak-to-trough value refers to the vertical distance between a crest and its adjacent trough.

Grinding Method:

Implementing periodic rail grinding (or milling) can eliminate or control the generation and development of rail corrugation.

Grinding should be performed by covering the entire rail surface, ensuring the achievement of the target profile.

Grinding should be performed by covering the entire rail surface, ensuring the achievement of the target profile.

Side Wear

Side wear typically appears as wear at the gauge corner, often accompanied by phenomena such as rolling contact fatigue. Concurrently, the bright band shifts towards the gauge corner side of the rail, and iron filings generated by wear are commonly found at the rail base.

Grinding Method:

The primary focus during grinding is the outer side of the rail crown, followed by covering the entire rail surface.

Lip (Flange) Formation

Lip formation typically manifests as a bulge caused by metal extrusion on the inner or outer side of the rail, often accompanied by defects such as rolling contact fatigue.

Grinding Method:

Grinding should focus on the side where the lip has formed. The objective is to ensure the elimination of both the lip and any associated fatigue damage at that location.

Rail Burn

Rail burns are mainly categorized into starting burns and braking burns.

Grinding Method:

For rail burns caused by locomotive, EMU, or self-propelled equipment startup, the rail should be replaced promptly. Other rail burns can be remedied using grinding or milling.

Rail Indentation (Battering)

Rail indentation is a phenomenon where foreign objects are pressed into the rail surface, forming indentations of a certain depth.

Grinding Method:

Rail indentations on main lines are remedied using grinding trains or small grinding equipment. Indentations on turnouts are addressed using turnout grinding trains or small grinding equipment. For severe indentations, milling or rail replacement is necessary.

Poor Profile

A poor rail profile directly worsens the wheel-rail contact relationship, leading to stress concentration, accelerated wear, and the initiation of track defects. It is often indicated by abnormal vibrations in EMUs.

Grinding Method:

Inspect and measure the rail profile. Based on the inspection results, arrange for rail profile design and grinding. After grinding, the rail profile should be close to or achieve the target profile.

WHY RailwayCare

Why Choose RailwayCare as Your Railway Mill Partner

Proven by History

Our products have been rigorously tested in China's diverse and demanding railway environments, from high-altitude, extreme-cold regions to heavily trafficked mainlines. Their reliability and adaptability have been fully validated.

Global Standards

From R&D to manufacturing, we strictly adhere to and integrate global technical specifications and safety standards, including those of the International Union of Railways (UIC), ensuring our products meet world-class compatibility and compliance.

Supply Chain Control

We have established a vertically integrated supply chain—from core raw materials to key production processes—enabling precise control over quality, cost, and delivery timelines to guarantee secure and stable supply.

Continuous Innovation

We focus on the iterative advancement of grinding technology and equipment, employing data-driven R&D to deliver solutions with higher efficiency and lower lifecycle costs.

Dedicated Support

We are committed to becoming your long-term technical partner, providing full lifecycle support—from project planning and product customization to on-site service and personnel training—to ensure your success.

Mileage refinement

Customers and Industry Achievements

China Beijing Railway Bureau has completed 4,000km of maintenance.

The Wuhan Railway Bureau of China has completed 3,500km of maintenance.

Chengdu Railway Bureau of China has accumulated 6,000km of track-up mileage.

faq

Frequently Asked Questions

Can RailwayCare large grinding trains adapt to our rail gauge and rail system?

Yes. RailwayCare provides both readily available solutions and custom engineering to meet diverse track requirements.

•Standard Gauge (1,435mm) Models: We have standard-design, high-performance grinding equipment ready for deployment on networks using the international standard gauge. This ensures a proven solution with optimized delivery timelines.

•Other Gauges (Broad & Narrow Gauge): For projects requiring different rail gauges (e.g., 1,520 mm, 1,676 mm, 1,000 mm, etc.), our core grinding technology platform is inherently adaptable. We can engineer and manufacture customized grinding trains to your specific gauge and operational requirements. This process begins with a detailed technical consultation to define the project scope.

•System Integration: Regardless of gauge, our engineering team will work with you to address integration aspects with your local rail system (signaling, power, regulations) to ensure safe and effective operation.

•Standard Gauge (1,435mm) Models: We have standard-design, high-performance grinding equipment ready for deployment on networks using the international standard gauge. This ensures a proven solution with optimized delivery timelines.

•Other Gauges (Broad & Narrow Gauge): For projects requiring different rail gauges (e.g., 1,520 mm, 1,676 mm, 1,000 mm, etc.), our core grinding technology platform is inherently adaptable. We can engineer and manufacture customized grinding trains to your specific gauge and operational requirements. This process begins with a detailed technical consultation to define the project scope.

•System Integration: Regardless of gauge, our engineering team will work with you to address integration aspects with your local rail system (signaling, power, regulations) to ensure safe and effective operation.

What are the equipment delivery lead times and training support like?

We strive for transparency and partnership throughout the delivery and commissioning process.

•Standard Configuration: For machines with standard specifications and common gauge adaptations, the typical delivery lead time is 4 to 6 months after order confirmation and receipt of down payment.

•Customized Configuration: For projects requiring significant customization or non-standard gauges, the lead time will be determined based on the technical complexity and mutually agreed upon in the contract. We will provide a detailed project timeline.

•Our comprehensive training program ensures your team can operate and maintain the equipment safely and effectively. It typically includes:

Operator & Maintenance Training: Conducted by our senior engineers during commissioning. Covers daily operation, basic troubleshooting, routine maintenance, and safety procedures.

•Classroom Theory Sessions: Deep dive into system principles, grinding strategy, and control software (if applicable).

•Detailed Documentation: Provision of complete operation manuals, maintenance guides, and parts catalogs in agreed languages.

•Optional Advanced Training: Available at our facility or on-site, focusing on advanced diagnostics, profile design, or fleet management.

How do I obtain spare parts and technical support?

We are committed to maximizing your equipment uptime through reliable after-sales support.

•Remote Support: Our technical support team is available during your business hours via email, phone, and remote diagnostic tools (if equipped) to provide immediate troubleshooting guidance.

•On-Site Service: For complex issues that cannot be resolved remotely, we can dispatch our service engineers to your site. Response time is based on the service level agreement (SLA).

•Preventive Maintenance Plans: We offer customized service contracts for periodic inspections and preventive maintenance to ensure long-term equipment health.

Get in contact

Ready to Build Your Grinding Strategy with Proven Technology?

Contact RailwayCare today. Let's discuss how our domestically-proven solutions can be tailored to enhance the safety, efficiency, and longevity of your railway assets.

Please send your message to us

- Name

- Phone

- *Title

- *Content