Rail Overheating & Blueing

- Burn marks on rails after grinding

- Bluish discoloration (temper colors) on rail surface

- Surface scratches or scoring after grinding

Track surface analysis using visual and ultrasonic inspection tools

Selection of grinding wheel type and parameters based on rail material and defect type.

Controlled removal of metal layers using specialized grinding wheels

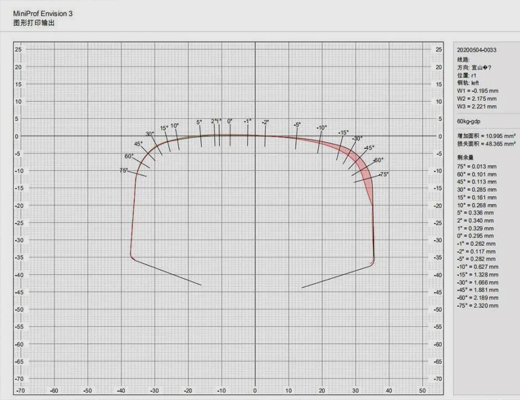

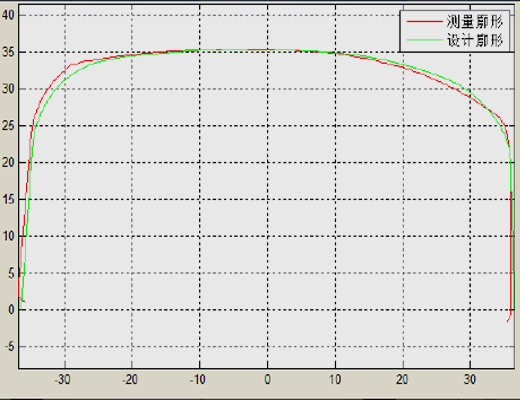

Rail geometry checked after grinding using profile gauges or optical systems

Periodic full inspection of mainline tracks covering geometry, surface, and internal defects for safety and smoothness.

Specialized inspection of turnout components including switches, frogs, and precise geometry measurement.

Enhanced inspection for curves with radius ≤600m, focusing on side wear, gauge, and geometry maintenance.

The target rail head profile is designed according to operational parameters (train type, axle load, speed, and track curvature).

Before determining the grinding process, a detailed track condition analysis is conducted to understand the rail’s structural and operational status.

It is a closed-loop workflow of precise analysis, controlled execution, and rigorous verification, ensuring every grinding action is justified and effective.

Grinding plans are developed based on rail material, defect severity, traffic conditions, axle load, speed, and track curvature.

We provide solutions for both mainline continuous grinding and localized turnout or corrective grinding.

Cost-effectiveness, ease of operation, long product lifespan, comprehensive technical support.

Collaborative grinding plan development + Grinding equipment (primarily grinding trains with matching wheels).

Maximum efficiency, low noise & dust emissions, night-time operation suitability, precision grinding.

Collaborative grinding plan development + Grinding equipment (primarily grinding trains with matching wheels)

Broad product coverage, high equipment availability, sufficient supply capacity.

Inspection services + Data analysis + Grinding plan formulation + Grinding equipment (primarily grinders with matching wheels)

Equipment portability & versatility, extreme cost-performance ratio, rapid technical support, flexible procurement options.

Grinding equipment (primarily grinders with matching wheels).

It can accurately measure rail profiles and calculate key parameters such as rail side wear, vertical wear, superelevation, track gauge, equivalent conicity, and wheel-rail contact characteristics.

Precision rail grinding vehicle for micro-defect removal and geometric restoration.

Precision grinding stones for rail profile restoration and surface defect elimination.

Precision rail thermite/flash-butt welding for seamless joint fusion and fatigue strength enhancement.

A Decade of Expertise, Millions of Kilometers of Experience With 10 years in the industry, we have accumulated 3 million kilometers of total rail grinding project experience, delivering proven practical expertise.

Complete Equipment Portfolio, Wide Applicability We supply a full range of grinding equipment and accessories suitable for all types of railways and environments, ensuring precise matching to your needs.

Expert Team with Industry Pedigree Our technical team is composed of core members from within China's railway system, bringing deep professional expertise and hands-on field capability.

Contributing to Industry Standards We have actively participated in and helped shape the formulation of grinding industry standards within China's railway system, committing to defining industry best practices.