Incomplete Coverage

- Blind Spots Exist

- Technology Limits

- Low Frequency

Inspection activities are initiated based on scheduled plans, condition-based triggers, or specific operational events to ensure timely and targeted assessment.

Inspection plans are defined with clear objectives, scope, and acceptance criteria, ensuring the right technologies, tools, and personnel are deployed for each task.

Inspection execution follows standardized procedures using onboard and field-based technologies to ensure accurate, complete, and traceable data collection.

This stage transforms raw inspection data into actionable insights through professional analysis, structured reporting, and long-term digital record management.

Strictly adheres to established maintenance schedules and periodic plans, ensuring disciplined preventive asset upkeep.

Triggered by real-time monitoring data (e.g., inspection vehicle exceedances, sensor alerts) for precise intervention.

Immediately launches specialized inspections following maintenance work, extreme weather, incidents, or abnormal patrol findings.

Defines specific track sections, key metrics, acceptance criteria, and expected deliverables.

Matches the most suitable inspection equipment, technology combinations (e.g., ultrasound vision), and expert teams.

Coordinate with other departments and teams to confirm the safe work period, and develop detailed on-site operating procedures, safety protocols, and contingency plans.

This involves the precise measurement of key parameters like gauge, alignment, and profile to ensure track smoothness, safety, and ride quality.

It employs non-destructive technologies like ultrasound to identify hidden internal flaws such as cracks, preventing critical rail failures.

This inspection identifies surface defects like wear and spalling to assess immediate rail condition and guide routine maintenance.

A specialized examination of critical components like switches and frogs, ensuring proper geometry and fit for safe operation and transition.

Achieving basic, critical self-inspection capabilities within a limited budget.

Collaborative Inspection plan development + Inspection equipment

Completing efficient, precise, and quiet inspection within extremely short “possession windows”.

Collaborative grinding plan development + Inspection equipment

Equipment must be highly versatile and mobile to support multiple fast-turnaround projects and maximize ROI.

Inspection services + Data analysis + plan formulation + Inspection equipment

Tackling high-difficulty, high-precision specialized inspection challenges to establish industry authority with cutting-edge technology.

Inspection equipment

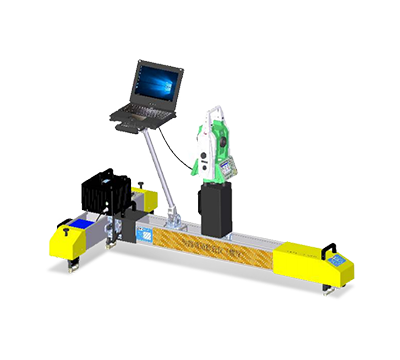

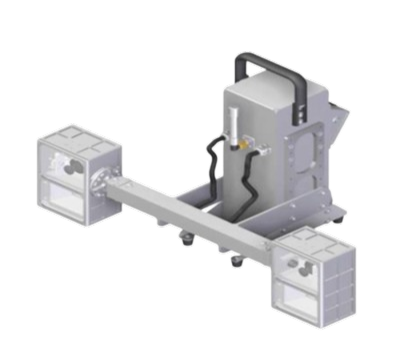

Railway track inspection systems (Inertial Navigation Based) support routine track patrols, maintenance operations, and precision alignment of newly constructed

Digital Track Gauge is an electronic inspection instrument that employs microcomputer-based control for the accurate measurement of static track geometry parameters.

It can accurately measure rail profiles and calculate key parameters such as rail side wear, vertical wear, superelevation, track gauge, equivalent conicity, and wheel-rail contact characteristics.

This system enables simultaneous inspection of track static geometric parameters and structural conditions, thereby enhancing the efficiency of inspection work.

A Decade of Expertise, Millions of Kilometers of Experience With 10 years in the industry, we have accumulated 3 million kilometers of total rail grinding project experience, delivering proven practical expertise.

Complete Equipment Portfolio, Wide Applicability We supply a full range of grinding equipment and accessories suitable for all types of railways and environments, ensuring precise matching to your needs.

Expert Team with Industry Pedigree Our technical team is composed of core members from within China's railway system, bringing deep professional expertise and hands-on field capability.

Contributing to Industry Standards We have actively participated in and helped shape the formulation of grinding industry standards within China's railway system, committing to defining industry best practices.