Step 1

Requirement Analysis & Technical Validation

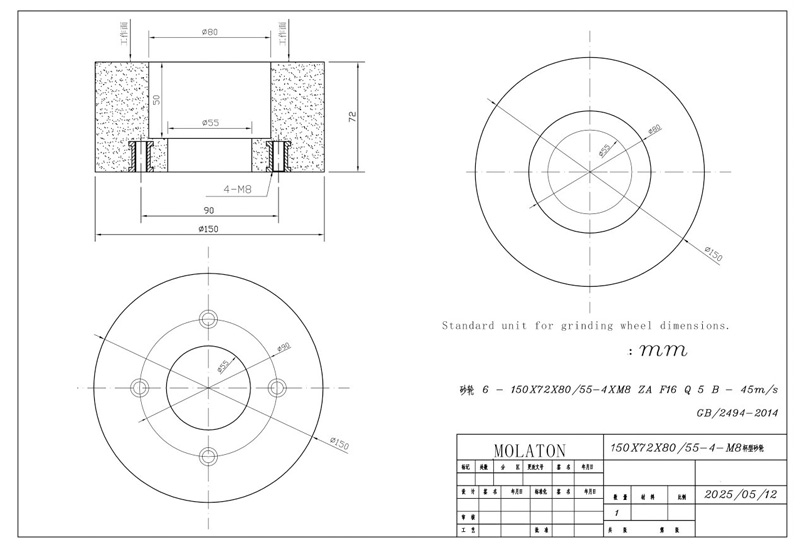

The client provides equipment parameters, operating condition requirements, design sketches, or samples. Technical teams from both sides collaborate to clarify all customization details and technical standards.

Step 2

Solution Development & Agreement Finalization

Based on the confirmed requirements, we develop a detailed technical proposal, including customized drawings, specifications, and commercial terms. Upon mutual confirmation, a formal cooperation agreement is executed.

Step 3

Prototype Production & Performance Verification

We first produce customized prototypes for your equipment installation testing and real-world operational validation. Bulk production commences only after confirming the product performance fully meets expectations.

Step 4

Batch Production & Process Control

Following prototype approval, batch production for the formal order is initiated. The entire process adheres to standardized quality management systems to ensure product consistency.

Step 5

Final Inspection & Quality Documentation

Each production batch undergoes rigorous physical/chemical performance testing and dimensional/visual inspection prior to shipment. Accompanying quality inspection reports ensure full data traceability.

Step 6

Branded Packaging & Logistics Delivery

Products are packaged according to the agreed branding specifications. Reliable international logistics are arranged to ensure safe and timely delivery to the designated location.