Detection Gaps

- Miss micro-cracks

- Near-surface blind zones

- Weather-related misses

Systematically collects track geometry and surface condition data using advanced technologies for early defect detection.

Conducts root-cause analysis of defects, accurately assesses their impact on safety and lifespan, and generates customized repair plans.

Executes targeted repairs using the most suitable processes and equipment to efficiently restore track health, as per the diagnostic plan.

Establishes an "inspection-remediation" feedback loop, using data to continuously refine maintenance strategies for predictive upkeep and maximized cost-effectiveness.

Regular manual checks build records for long-term trend analysis.

Mobile inspection uses peak/mean data to optimize track geometry.

Combines detection vehicles and manual patrols for internal/external flaw inspection.

Categorize defects by severity according to standards (e.g., Light, Medium, Heavy, Critical).

Determine if it's due to mechanical wear, material fatigue, improper maintenance, or external environment.

Determine the urgency of repair and the required repair solution.

Corrects track geometry and consolidates ballast for alignment stability.

Performs precise bolt hole drilling in rails and fittings for secure assembly.

Removes defective rail sections and prepares standard profiles for welding.

Joins rails seamlessly using flash-butt or thermite welding to eliminate joints.

Establish a digital archive to track the "life cycle" of each rail section.

Analyze historical data to predict rail wear and defect trends, enabling proactive maintenance planning.

Introduce more advanced inspection equipment (e.g., machine vision) and repair techniques.

Continuously improve and standardize operating procedures for maintenance tasks.

Achieving Safe & Compliant Operations within Limited Budgets

Collaborative grinding plan development + maintenance equipment

Achieving Zero-Disruption, High-Reliability Maintenance in Demanding

Collaborative grinding plan development + maintenance equipment

Maximizing Return on Equipment Assets and Project Profit Margins

Inspection services + Data analysis + maintenance plan formulation + maintenance equipment

Applying Top-Tier Technology to Solve Complex & Intractable Problems

Maintenance equipment

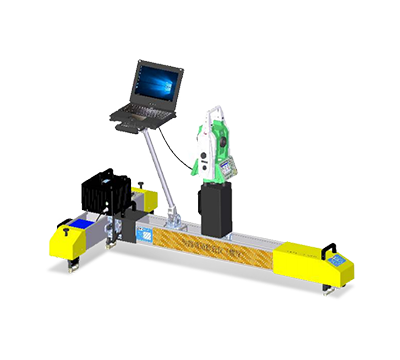

Railway track inspection systems (Inertial Navigation Based) support routine track patrols, maintenance operations, and precision alignment of newly constructed

Precision rail grinding vehicle for micro-defect removal and geometric restoration.

Precision grinding stones for rail profile restoration and surface defect elimination.

Precision rail thermite/flash-butt welding for seamless joint fusion and fatigue strength enhancement.

A Decade of Expertise, Millions of Kilometers of Experience With 10 years in the industry, we have accumulated 3 million kilometers of total rail grinding project experience, delivering proven practical expertise.

Complete Equipment Portfolio, Wide Applicability We supply a full range of grinding equipment and accessories suitable for all types of railways and environments, ensuring precise matching to your needs.

Expert Team with Industry Pedigree Our technical team is composed of core members from within China's railway system, bringing deep professional expertise and hands-on field capability.

Contributing to Industry Standards We have actively participated in and helped shape the formulation of grinding industry standards within China's railway system, committing to defining industry best practices.